Swiss scientists cut waste and sugar

Imogen Foulkes

Imogen FoulkesImagine picking up a nice juicy apple – but instead of biting into it you keep the seeds and throw the rest away.

That’s what chocolate producers have traditionally done with the cocoa fruit – used the beans and disposed of the rest.

But now food scientists in Switzerland have come up with a way to make chocolate using the entire cocoa fruit rather than just the beans – and without using sugar.

The chocolate, developed at Zurich’s prestigious Federal Institute of Technology by scientist Kim Mishra and his team includes the cocoa fruit pulp, the juice, and the husk, or endocarp.

The process has already attracted the attention of sustainable food companies.

They say traditional chocolate production, using only the beans, involves leaving the rest of the cocoa fruit – the size of a pumpkin and full of nutritious value – to rot in the fields.

The key to the new chocolate lies in its very sweet juice, which tastes, Mr Mishra explains, “very fruity, a bit like pineapple”.

This juice, which is 14% sugar, is distilled down to form a highly concentrated syrup, combined with the pulp and then, taking sustainability to new levels, mixed with the dried husk, or endocarp, to form a very sweet cocoa gel.

The gel, when added to the cocoa beans to make chocolate, eliminates the need for sugar.

Mr Mishra sees his invention as the latest in a long line of innovations by Swiss chocolate producers.

In the 19th Century, Rudolf Lindt, of the famous Lindt chocolate family, accidentally invented the crucial step of “conching” the chocolate – rolling the warm cocoa mass to make it smooth and reduce its acidity – by leaving a cocoa mass mixer running overnight. The result in the morning? Deliciously smooth, sweet chocolate.

Lindt

Lindt“You need to be innovative to maintain your product category,” says Mr Mishra. “Or… you will just make average chocolate.”

Mr Mishra was partnered in his project by KOA, a Swiss start-up working in sustainable cocoa growing. Its co-founder, Anian Schreiber, believes using the entire cocoa fruit could solve many of the cocoa industry’s problems, from the soaring price of cocoa beans to endemic poverty among cocoa farmers.

“‘Instead of fighting over who gets how much of the cake, you make the cake bigger and make everybody benefit,” he explains.

“The farmers get significantly extra income through utilising cocoa pulp, but also the important industrial processing is happening in the country of origin. Creating jobs, creating value that can be distributed in the country of origin.”

Mr Schreiber describes the traditional system of chocolate production, in which farmers in Africa or South America sell their cocoa beans to big chocolate producers based in wealthy countries as “unsustainable”.

Imogen Foulkes

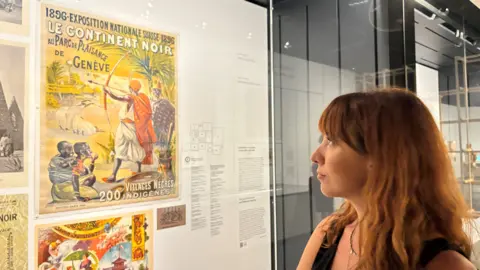

Imogen FoulkesThe model is also questioned by a new exhibition in Geneva, which explores Switzerland’s colonial past.

To those who point out that Switzerland never had any colonies of its own, chocolate historian Letizia Pinoja counters that Swiss mercenary soldiers policed other countries’ colonies, and Swiss ship owners transported slaves.

Geneva in particular, she says, has a particular link to some of the most exploitative phases of the chocolate industry.

“Geneva is a hub for commodity trade, and since the 18th Century, cocoa was reaching Geneva and then the rest of Switzerland to produce chocolate.

“Without this commodity trade of colonial goods, Switzerland could never have become the land of chocolate. And cocoa is no different from any other kind of colonial good. They all came from slavery.”

Nowadays, the chocolate industry is much more highly regulated. Producers are supposed to monitor their entire supply chain to make sure there is no child labour. And, from next year, all chocolate imported to the European Union must guarantee that no deforestation took place to grow the cocoa used in it.

But does that mean all the problems are solved? Roger Wehrli, director of the association of Swiss chocolate manufacturers, Chocosuisse, says cases of child labour and deforestation remain, particularly in Africa. He fears that some producers, in a bid to avoid the challenges, are simply shifting their production to South America.

“Does this solve the problem in Africa? No. I guess it would be better for responsible firms to stay in Africa and help to improve the situation.”

That is why Mr Wehrli sees the new chocolate developed in Zurich as “very promising… If you use the whole cocoa fruit, you can get better prices. So it’s economically interesting for the farmers. And it’s interesting from an ecological point of view.”

Chocosuisse

ChocosuisseThe link between chocolate production and the environment is also stressed by Anian Schreiber. A third of all farm produce, he says, “never ends up in our mouths”.

Those statistics are even worse for cocoa, if the fruit is abandoned to use only the beans. “It’s like you throw away the apple and just use its seeds. That’s what we do right now with the cocoa fruit.”

Food production involves significant greenhouse gas emissions, so reducing food waste could also help to tackle climate change. Chocolate, a niche luxury item, may not by itself be a huge factor, but both Mr Schreiber and Mr Wehrli believe it could be a start.

But, back in the laboratory, key questions remain. How much will this new chocolate cost? And, most important of all, without sugar, what does it really taste like?

The answer to the last question, in this chocolate-loving correspondent’s view, is: surprisingly good. A rich, dark but sweet flavour, with a hint of cocoa bitterness that would fit perfectly with an after dinner coffee.

The cost may remain something of a challenge, because of the global power of the sugar industry, and the generous subsidies it receives. “The cheapest ingredient in food will always be sugar as long as we subsidise it,” explains Kim Mishra. “For a… tonne of sugar, you pay $US500 [£394] or less.” Cocoa pulp and juice cost more, so the new chocolate would, for now, be more expensive.

Nevertheless, chocolate producers in countries where cocoa is grown, from Hawaii to Guatemala, to Ghana have contacted Mr Mishra for information about the new method.

Chocosuisse

ChocosuisseIn Switzerland, some of the bigger producers – including Lindt – are starting to use the cocoa fruit as well as the beans, but none, so far, has taken the step of eliminating sugar completely.

“We have to find daring chocolate producers who want to test the market and are willing to contribute to a more sustainable chocolate,” says Mr Mishra. “Then we can disrupt the system.”

Perhaps those daring producers will be found in Switzerland, whose chocolate industry makes 200,000 tonnes of chocolate each year, worth an estimated $US2bn. At Chocosuisse, Roger Wehrli sees a more sustainable, but still bright, future.

“I think chocolate will still taste fantastic in the future,” he insists. “And I think the demand will increase in the future due to the growing world population.”

And will they be eating Swiss chocolate? “Obviously,” he says.

Source link